BBC

BBCAmong the many cactuses within the desert of Arizona, simply outdoors Phoenix, a rare assortment of buildings is rising that may form the way forward for the worldwide financial system and the world.

The hum of additional development is creating not only a manufacturing facility for the world’s most superior semiconductors. Ultimately, it’s going to mass produce essentially the most superior chips on the earth. This work is being executed within the US for the primary time, with the Taiwanese firm behind it pledging to spend billions extra right here in a transfer geared toward heading off the specter of tariffs on imported chips.

It’s, in my opinion, crucial manufacturing facility on the earth, and it is being constructed by an organization you could not have heard of: TSMC, Taiwan Semiconductor Manufacturing Firm. It makes 90% of the world’s superior semiconductors. Till now they had been all made on the island of Taiwan, which is 100 miles east of the Chinese language mainland. The Apple chip in your iPhone, the Nvidia chips powering your ChatGPT queries, the chips in your laptop computer or laptop community, all are made by TSMC.

Its Arizona facility “Fab 21” is carefully guarded. Clean paper or private units are usually not allowed in case designs are leaked. It homes a few of the most essential mental property on the earth, and the method to make these chips is likely one of the most complex and intensive in world manufacturing.

They’re vastly protecting of the secrets and techniques that lie inside. Essential clients, reminiscent of Apple and Nvidia, belief this firm to safeguard their designs for future merchandise.

However after months of asking, TSMC let the BBC in to take a look at the partial switch of what some argue is essentially the most essential, costly, advanced and essential manufacturing on the earth.

The poster baby for Trump’s coverage

President Trump actually appears to suppose so. He typically mentions the manufacturing facility in passing. “TSMC is the largest there’s,” he has mentioned. “We regularly misplaced the chip enterprise, and now it is virtually solely in Taiwan. They stole it from us.” This is likely one of the US president’s common refrains.

TSMC’s current resolution to increase its investments within the US by an extra $100bn (£75bn) is one thing Trump attributes to his threats of tariffs on Taiwan and on the worldwide semiconductor enterprise.

The enlargement of the Arizona facility, which was introduced in March is, he believes, the poster baby for his financial insurance policies – particularly the encouragement of overseas corporations to relocate factories to the US to keep away from hefty tariffs.

Getty

GettyChina can also be watching developments fastidiously. Taiwan’s chip-making prowess has been a part of what its authorities has referred to as its “Silicon Defend”, towards a much-feared invasion. Whereas the unique technique was to make Taiwan indispensable on this space of essential know-how, the pandemic provide chain difficulties modified the calculus as a result of counting on a single nation appeared like a better danger.

China claims the self-ruled Taiwan as its territory however Taiwan sees itself as distinct from the Chinese language mainland.

So, many currents of the world financial system, frontier know-how and geopolitics movement by means of this one website and inside it lies the important contradiction of Trump’s financial and diplomatic coverage.

He sees this plant because the exemplar of America First, and the preservation of financial and army superiority over China. But the manufacture of those fashionable miniaturised miracles on the frontier of physics and chemistry inherently depends on a mixture of the perfect applied sciences from world wide.

The cleanest setting on Earth

Greg Jackson, one of many services managers, takes me round in a golf buggy. The factories are virtually a carbon copy of the TSMC areas in Taiwan, the place he educated. “I’d say these services are in all probability a few of the most superior and sophisticated on the earth,” he says.

“It is fairly the dichotomy. You’ve got received actually, actually small chips with actually small buildings, and it takes this huge facility with all of the infrastructure to have the ability to make them… Simply the sheer complexity, the quantity of techniques that it takes, is staggering.”

Contained in the “Gowning Constructing”, employees costume in protecting clothes earlier than crossing a bridge that’s presupposed to create the cleanest setting on Earth, with a view to defend the manufacturing of those extraordinary microscopic transistors that create the microchips underpinning all the things.

Konstantinos Ninios, an engineer, exhibits me a few of the very first productions from TSMC Arizona: a silicon wafer with what is named “4 nanometre chips”.

“That is essentially the most superior wafer within the US proper now,” he explains. “[It] comprises about 10 to 14 trillion transistors… The entire course of is 3,000 to 4,000 steps.”

Should you may one way or the other shrink your physique to the identical scale and get contained in the wafer, he says that the numerous completely different layers would appear to be very tall streets and skyscrapers.

Manufacturing manipulation of atoms

TSMC was based on the behest of the Taiwanese authorities in 1987, when chip govt Morris Chang was directed to start out the enterprise. The mannequin was to develop into a devoted foundry for microchips, manufacturing different corporations’ designs. It grew to become wildly profitable.

Driving the development of the know-how is the miniaturisation of the smallest function on chips. Their dimension is measured lately in billionths of a metre or nanometres. This progress has enabled cell phones to develop into smartphones, and is now setting the tempo for the mass deployment of synthetic intelligence.

It requires unbelievable complexity and expense by means of using “excessive ultraviolet (UV) mild”. That is used to etch the intricate constructing blocks of our fashionable existence in a course of referred to as “lithography”.

The world’s dependence on TSMC is constructed on extremely specialised bus-sized machines, that are in flip sourced virtually completely from a Dutch firm referred to as ASML, together with in Arizona.

These machines shoot UV mild tens of 1000’s of occasions by means of drops of molten tin, which creates a plasma, and is then refracted by means of a sequence of specialized mirrors.

The virtually completely automated course of for every wafer of silicon is repeated 1000’s of occasions in layers over months, earlier than the $1m LP-sized wafer of 4nm silicon chips is shaped.

“Simply think about a particle or a mud particle falling into this,” Mr Ninios says to me incredulously. “The transistors are usually not going to work. So all of that is cleaner than hospital working rooms.”

Warning in Taiwan

Taiwan doesn’t have particular entry to the uncooked supplies – however it has the know-how to remain years forward of different corporations within the intricate course of of manufacturing these atomic constructing blocks of contemporary life.

Some within the Taiwanese authorities are cautious about spreading the frontier of this know-how off the island. Trump wasted little time in claiming the agency’s resolution to deliver its highest stage of know-how to the US was because of his financial insurance policies.

He mentioned this is able to not have occurred with out the stick of his deliberate tariffs on Taiwan and semiconductors. These I converse to at TSMC are diplomatic about that declare.

A lot of this was already deliberate and subsidised underneath former US President Biden’s Chips Act.

On the walkway into the constructing are pictures displaying Biden’s go to in 2022, with the constructing website draped within the Stars and Stripes and a banner saying “a future Made in America”.

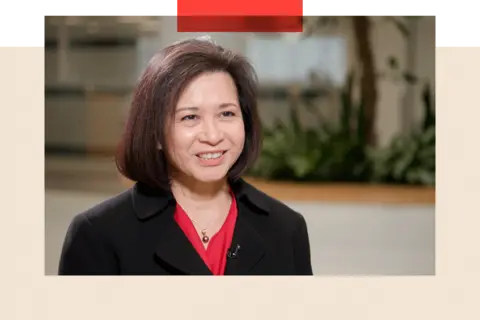

“The semiconductor provide chain is world,” says TSMC Arizona President Rose Castanares. “There’s actually no single nation at this second that may do all the things from chemical compounds to wafer manufacturing to packaging, and so it is very tough to unwind that entire factor in a short time.”

‘Non-Crimson’ provide chains to counter China

As for the semiconductor provide chain, tariffs won’t assist. The provision chain stretches everywhere in the world. Whether or not it is the silicon wafers from Japan, the machines required from the Netherlands, or mirrors from Germany, all kinds of supplies from all world wide are required. Now, they may face import costs.

That mentioned, TSMC’s boss was fast off the mark in confirming the enlargement of the US website at an occasion with Trump on the White Home. In current weeks, America’s tech elite – from Apple’s Tim Prepare dinner, to Nvidia’s Jensen Huang – have been queueing as much as inform the world that TSMC Arizona will now produce lots of the chips of their US merchandise.

The worldwide chip business may be very delicate to the financial cycle, however its cutting-edge know-how enjoys very wholesome margins, that might cushion a few of these deliberate tariffs.

There are numerous geopolitical subtexts right here. The manufacturing facility sits on the coronary heart of US technique to realize technological, AI and financial supremacy over China.

Each the Biden and Trump administrations have developed insurance policies to try to restrict Chinese language entry to the frontier semiconductor know-how – from a ban on exports to China of ASML’s machines, to new laws to ban using Huawei AI chips in US software program or know-how wherever on the earth.

Taiwan’s President Lai this week urged democracies reminiscent of Japan and the US to develop “non-Crimson” provide chains to counter China.

Not everyone seems to be satisfied that this technique is working, nevertheless. Chinese language technologists have been efficient at working across the bans to develop aggressive indigenous know-how. And Invoice Gates this week mentioned that these insurance policies “have compelled the Chinese language when it comes to chip manufacturing and all the things to go full pace forward”.

Trump needs TSMC Arizona to develop into a basis stone for his American golden age. However the firm’s story to this point is probably the last word expression of the success of contemporary globalisation.

So for now, it is a battle for world tech and financial supremacy, wherein Taiwan’s manufacturing facility know-how, a few of which is now being moved to the Arizona desert, is the essential asset.

BBC InDepth is the house on the web site and app for one of the best evaluation, with recent views that problem assumptions and deep reporting on the largest problems with the day. And we showcase thought-provoking content material from throughout BBC Sounds and iPlayer too. You’ll be able to ship us your suggestions on the InDepth part by clicking on the button beneath.