Ben MorrisExpertise of Enterprise Editor

A stream of scorching caramel runs by means of the Thomas Tunnock manufacturing unit simply exterior Glasgow.

From the second ground the place it’s made, it runs alongside conveyor belts right down to the primary ground, bringing a a candy, heat aroma to the constructing.

However working with caramel shouldn’t be simple. Skilled staff must verify that it’s on the proper consistency, and it takes a group of 12 to unfold the caramel in 5 layers that make up the Tunnock’s wafer biscuit.

“We’re making roughly 20 tonnes of caramel a day,” says Stuart Louden, the agency’s engineering and transport supervisor, and the fifth era of the Tunnock household to work on the enterprise.

“Operators do loads of caramel testing, simply on sight and on really feel. So mainly, they stroll as much as the caramel and simply give it a squeeze.”

As soon as made, a conveyor belt takes the caramel right down to the ground under, the place the spreading group works.

“Spreading caramel onto wafers could be very, very tough as a result of it is so sticky,” says Mr Louden.

Whereas this can be a labour intensive a part of the Tunnock’s operation, many of the remainder of the manufacturing unit is automated.

The corporate has at all times tried to make use of the most recent know-how to assist sustain with the competitors. In contrast with the snack giants like McVitie’s or Fox’s, Tunnock’s is a small participant.

“We’re a small fish in a giant pond, and to attempt to sustain with a few of these greater corporations that we’re competing in opposition to, you have to have the nice machines there to get the output,” says Mr Louden.

They do have machines to unfold the caramel, which work at night time, however the human workforce is extra versatile and takes up much less area.

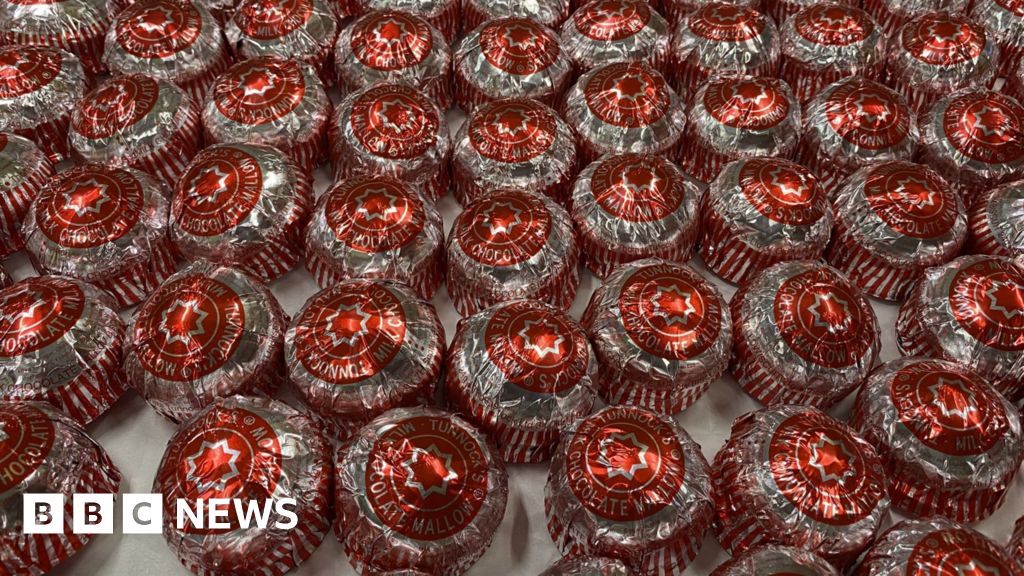

Between them, the machines and people prove round seven million wafer bars and 4.5 million tea truffles a 12 months.

Elevating output is usually a balancing act for the agency, between sustaining their traditions and growing output.

For instance, like their caramel manufacturing, Tunnock’s marshmallow is made below shut human supervision.

In the meantime, the wrapping of the wafer bar is folded across the product, somewhat than sealed on the ends. If Tunnock’s switched to sealing then the manufacturing line might run extra rapidly.

“It is a good factor. In the event you give individuals a caramel wafer, and any person’s not had one for 20 or 30, years, they go, ‘I keep in mind having considered one of these after I was a child’.”

The makers of a brand new robotic arm for the cake trade are hoping to bridge that hole between pace and custom.

Canada’s Unifiller, a part of Coperion a giant maker of apparatus for meals manufacturing, spent years growing a robotic arm, known as HIRO.

It is designed to embellish truffles and might deal with all kinds of toppings, together with caramel.

“In the event you can squeeze it by means of a pastry bag… then it is going to undergo our gear and the the adorning suggestions,” says Derek Lanoville, the analysis and growth supervisor at Coperion.

However making gear for the meals trade entails additional challenges – maybe the most important being hygiene.

“You must make issues simple to take aside, so that individuals clear them. The underside line is, if it is not simple to take aside, you do not clear it.”

Unifiller’s robotic arm comes from Swiss robotics agency Stäubli, which might provide an arm that is simple to wash.

One other complication is the variability of meals merchandise like truffles.

On manufacturing strains in most industries parts would be the identical dimension, typically to inside fractions of a millimetre. That is not the case in baking, the place the truffles rolling down a line will likely be completely different – not by a lot – however sufficient,maybe, to upset a robotic.

“The cake is probably not completely centred on the cardboard it is sitting on. It might be a little bit bit oval, could also be a little bit bit larger or barely domed. So, our answer has to accommodate that,” says Mr Lanoville.

For Anomarel Ogen, human palms are nonetheless important to the baking course of.

Mr Ogen is head baker at The Bread Manufacturing unit, which is the place merchandise for the café chain Gail’s are baked.

Their bakery in northwest London runs 24 hours a day and twelve months a 12 months, supplying sourdough loaves to Gail’s, in addition to supermarkets, retailers and eating places.

It makes use of round 16 tonnes of flour to provide as much as 40,000 loaves a day, which seems like so much however, in contrast with the large bakers, continues to be a medium-sized enterprise.

Machines combine the dough and divide it into into smaller, loaf-sized portions.

They use a variety of flours which are farmed utilizing sustainable strategies that prioritise soil well being.

Mr Ogen says which means their dough is delicate. We watch considered one of their staff forming loaves from the dough.

“Take a look at his palms, and look how mild he really is with the motion, how little stress he’s really placing in. That requires years of talent. This isn’t absolutely replaceable by machines simply but,” says Mr Ogen.

Having employees within the manufacturing unit additionally provides flexibility to the manufacturing course of. If the recipe is tweaked, they will monitor the affect that has on the dough and alter the baking course of, if mandatory.

“You possibly can automate extra, however you continue to must put in gatekeeping proper alongside the trail, to just be sure you can safeguard the method,” says Mr Ogen.

Introducing new tech to a manufacturing line is at all times a steadiness, says Craig Le Clair, principal analyst on the analysis agency Forrester, and in addition the writer of Random Acts of Automation: Find out how to Battle Again When Automation Threatens Your Work, Your Life, and All the pieces You Do.

“The important thing in meals in addition to different industries is growing a hybrid mannequin that integrates automation with out shedding the “soul” of a handcrafted product, like a embellished cake.

“Course of transformation should apply automation solely to areas that profit from consistency, pace, and quantity, whereas conserving core value-add parts strictly human,” he says.

Again at gear maker Coperion, Mr Lanoville has plans to develop the robotic arm additional.

“What we’re targeted on this 12 months is actually nailing down our scanning, imaginative and prescient and and security programs in order that, in order that our our prospects can work the best way that they work, with out the robotic being intrusive.”

In the meantime in Glasgow, Mr Louden has plans to improve his manufacturing line, however a lot hinges on the monetary atmosphere. Cocoa costs have been unstable over the previous two years, which has a big effect on his agency.

“Relating to investing one other two-and-a-half million kilos in gear, we simply want to attend, as a result of the final couple of years simply haven’t been the precise time, and we do not need to put ourselves financially able that it might harm us.”