Trendy high-performance chips are marvels of engineering, containing tens of billions of transistors. The issue is, you possibly can’t use them . In the event you did, you’ll create scorching spots—excessive temperatures concentrated in tiny areas—with energy densities nearing these discovered on the floor of the solar. This has led to a irritating paradox generally known as dark silicon, a time period coined by pc architects to explain the rising portion of a chip that should be stored powered down. As much as 80 p.c of the transistors on a contemporary chip should stay “darkish” at any given second to maintain the chip from scorching. We’re constructing supercomputers on a sliver of silicon however solely utilizing a fraction of their potential. It’s like constructing a skyscraper and having the ability to use solely the primary 10 flooring.

For years, the trade has battled this thermal restrict with greater followers and extra advanced liquid cooling programs. However these are basically Band-Help options. Whether or not utilizing air or liquid, they depend on pulling warmth away from the chip’s floor. The warmth should first conduct by means of the silicon to the cooling plate, making a thermal bottleneck that merely can’t be overcome on the energy densities of future chips. Scorching spots on as we speak’s chips produce tens of watts per sq. millimeter, and so they pop up in varied locations on the chip at completely different occasions throughout computations. Air and liquid cooling wrestle to focus their efforts at simply the recent spots, when and the place they seem—they’ll solely attempt to cool the entire thing en masse.

We at St. Paul, Minn.–primarily based startup Maxwell Labs are proposing a radical new strategy: What if, as an alternative of simply shifting warmth, you might make it disappear? The expertise, which we name photonic cooling, is able to changing warmth instantly into mild—cooling the chip from the within out. The vitality can then be recovered and recycled again into helpful electric power. With this strategy, as an alternative of cooling the entire chip uniformly, we will goal scorching spots as they kind, with laser precision. Basically, this system may cool scorching spots of 1000’s of watts per sq. millimeter, orders of magnitude higher than as we speak’s chips are cooled.

The Physics of Cooling With Gentle

Lasers are often regarded as sources of warmth, and for good motive—they’re mostly used for slicing supplies or transferring information. However beneath the appropriate circumstances, laser mild can induce cooling. The key lies in a luminescent course of generally known as fluorescence.

Fluorescence is the phenomenon behind the acquainted glow of highlighter markers, coral reefs, and white garments beneath black-light illumination. These supplies take up high-energy mild—often within the ultraviolet—and reemit decrease vitality mild, usually within the seen spectrum. As a result of they take up greater vitality than they emit, the distinction usually leads to heating up the fabric. Nevertheless, beneath sure, very area of interest circumstances, the alternative can occur: A cloth can take up low-energy photons and emit higher-energy mild, cooling down within the course of.

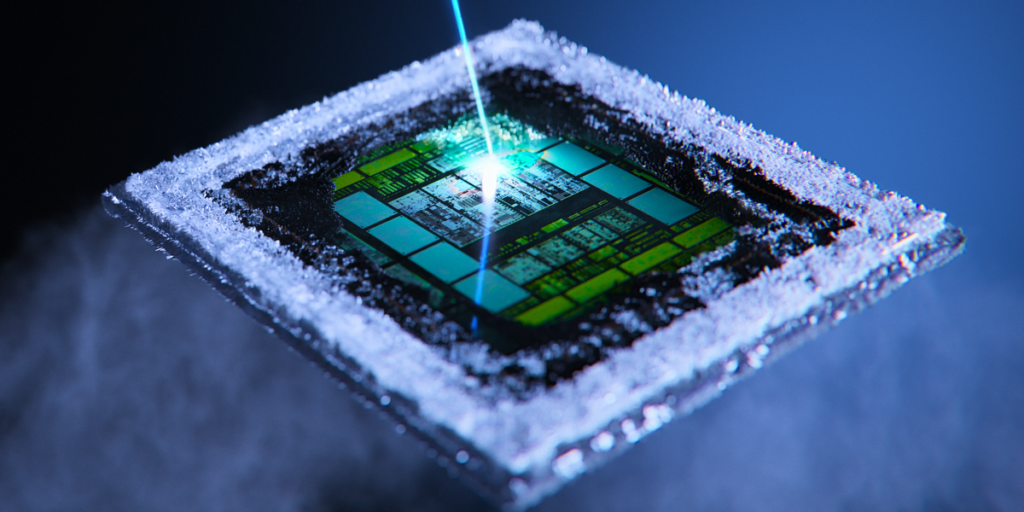

To chill computer chips with lasers, the staff at Maxwell Labs plans to put a grid of photonic chilly plates on prime of the chip substrate. Of their demo setup, a thermal digital camera detects scorching spots coming from the chip. A laser then shines onto the photonic chilly plate subsequent to the recent spot, stimulating the photonic course of that leads to cooling. The photonic chilly plate [inset] consists of a coupler that guides mild out and in of the plate, the extractor the place anti-Stokes fluorescence happens, the again reflector that forestalls mild from coming into the pc chip, and a sensor that’s designed to detect scorching spots.GygInfographics.com

The reemission is greater vitality as a result of it combines the vitality from the incoming photons with phonons, vibrations within the crystal lattice of a cloth. This phenomenon known as anti-Stokes cooling, and it was first demonstrated in a strong again in 1995 when a staff of scientists cooled an ytterbium-doped fluoride glass pattern with laser mild.

The selection of ytterbium as a dopant was not random: Anti-Stokes cooling works solely beneath rigorously engineered circumstances. The absorbing materials should be structured in order that for almost each absorbed photon a higher-energy photon can be emitted. In any other case, different mechanisms will kick in, heating slightly than cooling the pattern. Ions of ytterbium and different such lanthanides have the appropriate construction of electron orbitals to facilitate this course of. For a slim vary of laser wavelengths shining on the fabric, the ions can successfully take up the incident mild and use phonons to set off emission of higher-energy mild. This reemitted, extracted thermal mild wants to flee the fabric rapidly sufficient to not be absorbed once more, which might in any other case trigger heating.

To this point, lab-based approaches have achieved as much as 90 watts of cooling energy in ytterbium-doped silica glass. As spectacular as that’s, to realize the transformative results on high-performance chips that we anticipate, we have to enhance the cooling capability by many orders of magnitude. Reaching this requires integration of the photonic cooling mechanism onto a thin-film, chip-scale photonic chilly plate. Miniaturization not solely allows extra exact spatial focusing on of scorching spots because of the tightly targeted beam, however is an important ingredient for pushing the physics of laser cooling towards high-power and high-efficiency regimes. The thinner layer additionally makes it much less probably that the sunshine will get reabsorbed earlier than escaping the movie, avoiding heating. And, by engineering the supplies on the scale of the wavelength of sunshine, it permits for elevated absorption of the incoming laser beam.

Photonic Chilly-Plate Know-how

In our lab, we’re creating a solution to harness photonic cooling to deal with the warmth from as we speak’s and future CPUs and GPUs. Our photonic chilly plate is designed to sense areas of accelerating power density (rising scorching spots) after which couple mild effectively into a close-by area that cools the recent spots right down to a goal temperature.

The photonic chilly plate has a number of elements: first the coupler, which {couples} the incoming laser mild into the opposite elements; then, the microrefrigeration area, the place the cooling really occurs; subsequent, the again reflector, which prevents mild from hitting the CPU or GPU instantly; and final a sensor, which detects the recent spots as they kind.

The laser shines onto the focused space from above by means of the coupler: a sort of lens that focuses the incoming laser mild onto a microrefrigeration area. The coupler concurrently channels the inbound heat-carrying fluorescent mild out of the chip. The microrefrigeration area, which we name the extractor, is the place the true magic occurs: The specifically doped thin film undergoes anti-Stokes fluorescence.

To stop the incoming laser mild and fluorescent mild from coming into the precise chip and heating the electronics, the photonic chilly plate incorporates a again reflector.

Crucially, cooling happens solely when, and the place, the laser is shining onto the chilly plate. By selecting the place to shine the laser, we will goal scorching spots as they seem on the chip. The chilly plate features a thermal sensor that detects scorching spots, permitting us to steer the laser towards them.

Designing this complete stack is a fancy, interconnected downside with many adjustable parameters, together with the precise form of the coupler, the fabric and doping stage of the extraction area, and the thickness and variety of layers within the again reflector. To optimize the chilly plate, we’re deploying a multiphysics simulation mannequin mixed with inverse design tools that permit us search the huge set of potential parameters. We’re leveraging these instruments within the hope of enhancing cooling energy densities by two orders of magnitude, and we’re planning bigger simulations to realize greater enhancements nonetheless.

Collaborating with our companions on the College of New Mexico in Albuquerque, the College of St. Thomas in St. Paul, Minn., and Sandia National Laboratories in Albuquerque, we’re constructing an illustration model of photonic cooling at our lab in St. Paul. We’re assembling an array of small photonic chilly plates, every a sq. millimeter in dimension, tiled atop varied CPUs. For demonstration functions, we use an exterior thermal digital camera to sense the recent spots coming from the chips. When a scorching spot begins to seem, a laser is directed onto the photonic chilly plate tile instantly atop it, extracting its warmth. Our first iteration of the chilly plate used ytterbium ion doping, however we at the moment are experimenting with quite a lot of different dopants that we imagine will obtain a lot greater efficiency.

In an upcoming built-in implementation of this demo, the photonic chilly plates will encompass finer tiles—about 100 by 100 micrometers. As an alternative of a free-space laser, mild from a fiber can be routed to those tiles by an on-chip photonic community. Which tiles are activated by the laser mild will depend upon the place and when scorching spots kind, as measured by the sensor.

Finally, we hope to collaborate with CPU and GPU producers to combine the photonic chilly plates inside the similar package deal because the chip itself, permitting us to get the essential extractor layer nearer to the recent spots and enhance the cooling capability of the system.

The Laser-Cooled Chip and the Information Middle

To know the affect of our photonic cooling expertise on present and future data centers, we’ve carried out an evaluation of the thermodynamics of laser cooling mixed with and in comparison with air and liquid cooling approaches. Preliminary outcomes present that even a first-generation laser-cooling setup can dissipate twice the ability of purely air and liquid cooling programs. This drastic enchancment in cooling functionality would permit for a number of key adjustments to chip and data-center architectures of the long run.

First, laser cooling may remove the dark-silicon downside. By sufficiently eradicating warmth from scorching spots as they’re forming, photonic cooling would allow simultaneous operation of extra of the transistors on a chip. That will imply all of the useful models on a chip may perform in parallel, bringing the total pressure of recent transistor densities to bear.

Second, laser cooling can permit for a lot greater clocking frequencies than is presently potential. This cooling approach can keep the chip’s temperature beneath 50 °C all over the place, as a result of it targets scorching spots. Present-generation chips sometimes expertise scorching spots within the 90-to-120 °C vary, and that is expected only to get worse. The power to beat this bottleneck would permit for greater clocking frequencies on the identical chips. This opens up the potential of enhancing chip efficiency with out instantly growing transistor densities, giving a lot wanted headroom for Moore’s Regulation to proceed to progress.

The demo setup at Maxwell Labs demonstrates how present pc chips could be cooled with lasers. A photonic chilly plate is positioned on prime of the chip. A thermal digital camera photos the recent spots coming from the chip, and a laser is directed on the photonic chilly plate instantly above the recent spot.Maxwell Labs

The demo setup at Maxwell Labs demonstrates how present pc chips could be cooled with lasers. A photonic chilly plate is positioned on prime of the chip. A thermal digital camera photos the recent spots coming from the chip, and a laser is directed on the photonic chilly plate instantly above the recent spot.Maxwell Labs

Third, this expertise makes 3D integration thermally manageable. As a result of laser-assisted cooling pinpoints the recent spots, it will possibly extra readily take away warmth from a 3D stack in a manner that as we speak’s cooling tech can’t. Including a photonic chilly plate to every layer in a 3D built-in stack would care for cooling the entire stack, making 3D chip design rather more easy.

Fourth, laser cooling is extra environment friendly than air cooling programs. An much more tantalizing results of the removing of warmth from scorching spots is the power to maintain the chip at a uniform temperature and enormously scale back the general energy consumption of convective cooling programs. Our calculations present that, when mixed with air cooling, reductions in general vitality consumption of greater than 50 p.c for present era chips are potential, and considerably bigger financial savings could be achieved for future chips.

What’s extra, laser cooling permits for recovering a a lot greater fraction of waste vitality than is feasible with air or liquid cooling. Recirculating scorching liquid or air to warmth close by homes or different services is feasible in sure areas and climates, however the recycling effectivity of those approaches is proscribed. With photonic cooling, the sunshine emitted by way of anti-Stokes fluorescence could be recovered by re-collecting the sunshine into fiber-optic cables after which changing it to electrical energy by means of thermophotovoltaics, resulting in upwards of 60 p.c vitality restoration.

With this basically new strategy to cooling, we will rewrite the principles by which chips and information facilities are designed. We imagine this may very well be what allows the continuation of Moore’s Regulation, in addition to the ability financial savings on the data-center stage that might greenlight the intelligence explosion we’re beginning to see as we speak.

The Path to Photonic Cooling

Whereas our outcomes are extremely promising, a number of challenges stay earlier than this expertise can turn into a business actuality. The supplies we’re presently utilizing for our photonic chilly plates meet primary necessities, however continued growth of upper effectivity laser-cooling supplies will enhance system efficiency and make this an more and more economically enticing proposition. To this point, solely a handful of supplies have been studied and made pure sufficient to permit laser cooling. We imagine that miniaturization of the photonic chilly plate, aided by progress in optical engineering and thin-film supplies processing, can have equally transformative results on this expertise because it has for the transistor, photo voltaic cells, and lasers.

We’re going to want to codesign the processors, packages, and cooling programs to maximise advantages. This may require shut collaboration throughout the historically siloed semiconductor ecosystem. We’re working with trade companions to attempt to facilitate this codesign course of.

Transitioning from a lab-based setup to high-volume business manufacturing would require us to develop environment friendly processes and specialised tools. Business-wide adoption necessitates new requirements for optical interfaces, security protocols, and efficiency metrics.

Though there’s a lot to be completed, we don’t see any elementary obstacles now to the large-scale adoption of photonic cooling expertise. In our present imaginative and prescient, we anticipate the early adoption of the expertise in high-performance computing and AI coaching clusters earlier than 2027, displaying an order-of-magnitude enchancment in efficiency per watt of cooling. Then, between 2028 and 2030, we hope to see mainstream data-center deployment, with an accompanied discount in IT vitality consumption of 40 p.c whereas doubling compute capability. Lastly, after 2030 we foresee that ubiquitous deployment, from hyperscale to edge, will allow new computing paradigms restricted solely by algorithmic effectivity slightly than thermal constraints.

For over twenty years, the semiconductor industry has grappled with the looming risk of darkish silicon. Photonic cooling presents not merely an answer to that problem however a elementary reimagining of the connection between efficiency, computation, and vitality. By changing waste heat instantly into helpful photons and in the end again into electrical energy, this expertise transforms thermal management from a crucial evil right into a beneficial useful resource.

The way forward for computing is photonic, environment friendly, and brilliantly cool.

From Your Website Articles

Associated Articles Across the Net